Monthly Archives: January 2015

“Skraw-Met” shot-blasting machine

before cleaning pic. no 1

after cleaning pic. no 2

“skraw-met” machinery

|

Machine facilities ⇒ CNC plasma and gas cutter (2 x 3 m) ⇒ hydraulic presses, 40 – 200 t ⇒ guillotine shear, 3.0 m (max. up to 14 mm) ⇒ universal turning machines ⇒ vertical and horizontal milling machines ⇒ pillar and radial drills ⇒ band saws (max. 800 x 460 – W x H mm) ⇒ shot-blasting chamber (max. 2 x 2 x 2 m) ⇒ technological line for powder coating (4.2 x 1.2 x 1.9 – LxWxH m) ⇒ hydrodynamic coating chamber (5 x 4 x 2.5 – LxWxH) with heating up to the temperature of 80°C |

“skraw-met” home

|

SKRAW-MET Mechanical Plant has been operating since 1993. Currently we are employing several dozens of people who are specialists in their fields. The company structure allows us to quickly and flexibly respond to the needs of our customers. Our strength is flexibility and a wide range of offer, from manufacturing to installation and coating. Our team of specialists is capable of adjusting to customers’ needs and offering optimum solutions. Our machinery stock and expertise allow us to manufacture products of different complexity levels. We provide services in metal machining. We specialise in manufacturing metal machinery and equipment components as part of cooperation, trailer tow-bars, various small- and medium-sized steel structures, spare parts for agricultural machinery, equipment for front and rear loaders as well as equipment manufactured as part of cooperation with third parties. Our parts are manufactured based on our extended expertise and cooperation with users.

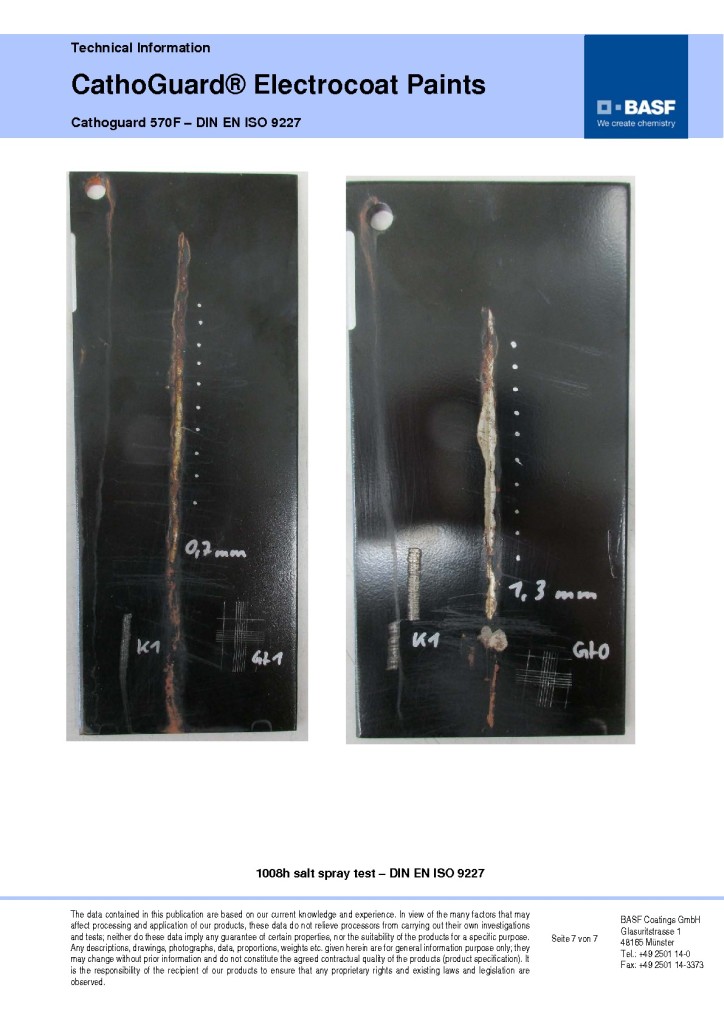

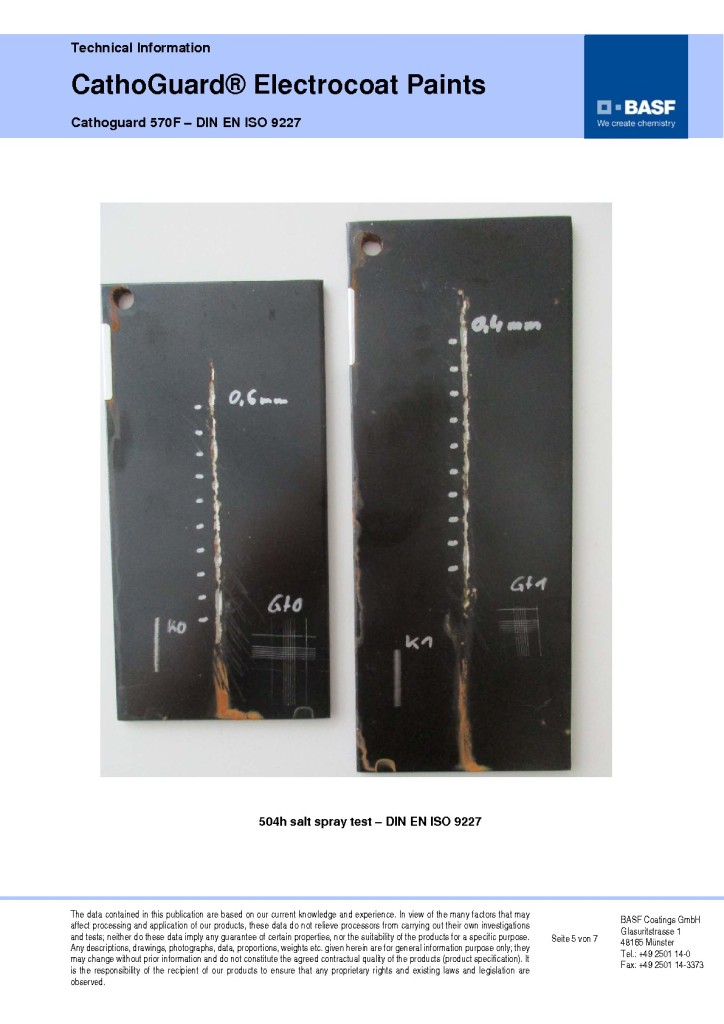

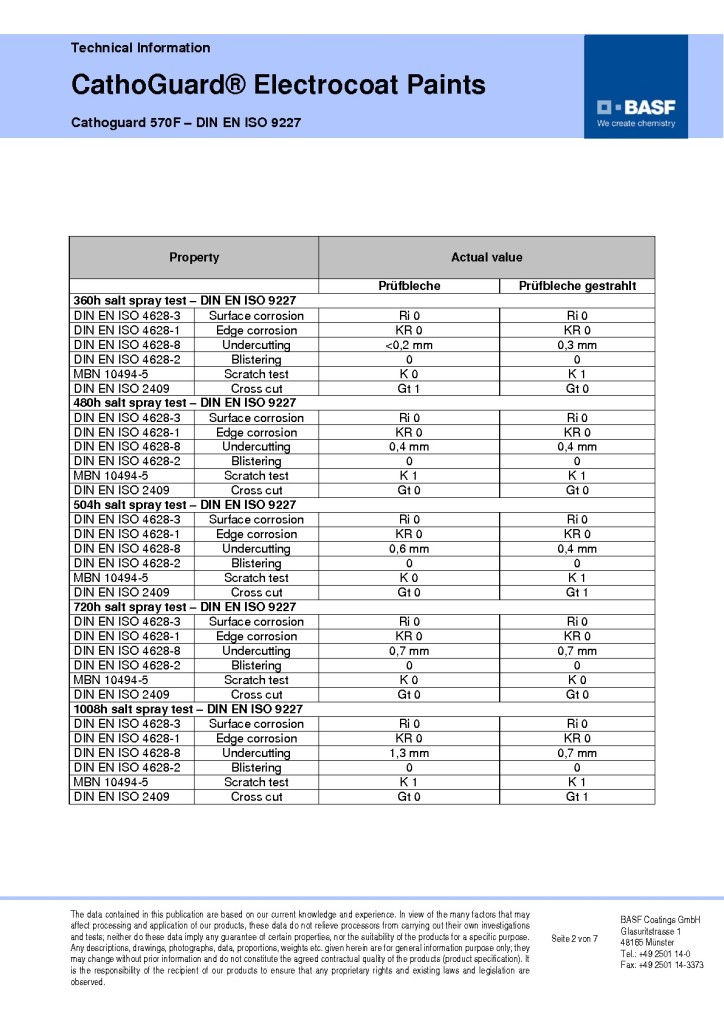

We also provide the services of CNC cutting, electrophoretic coating (electropainting), powder coating and coating with liquid paints. With such a wide range of processes we can offer a full range of protective and decorative coats as well as multi-layer coating. We coat workpieces made of steel, cast iron, forged, aluminium and light alloys as well as workpieces that make a combination of several materials once assembled. Our plant provides the following services:

ZM SKRAW-MET COMPANY HAS IMPLEMENTED AND APPLIES A QUALITY MANAGEMENT SYSTEM COMPLIANT WITH PN-EN ISO 9001:2015 STANDARD REQUIREMENTS FOR CATAPHORETIC COATING that defines the rules for regular supervision over individual steps affecting the quality of manufactured products and services. The International Quality Management System confirms our capacity to meet high quality requirements. The cataphoretic coating is one of the best methods for protecting metal parts against corrosion. We are a reliable and proven partner. |

“skraw-met” contacts

|

Adress

E-mail: |

ul. Demokracji 39 74-400 Dębno, zachodniopomorskie Poland skrawmet@wp.pl |

|

Phone |

[ +48(95) 769 33 58 ] |

| Fax | [ +48(95) 769 03 25 ] |

|

Managing personnel: |

Julian Mierzwiński – Proprietor |

|

Mobile

|

+48 510 236 609 |

|

NIP (tax id. no.) |

597-100-31-85 |

|

REGON (Nat. Bus. id. no.) |

210171621 |

“skraw-met” offer

|

ZM SKRAW-MET is a company that carries out:

|

Polski

Polski Deutsch

Deutsch English

English